Laser beam diagnostics:

What if Star Wars had deployed the ISO 11146 standard for laser beam diagnostics? We can’t rewrite history, but we can still delve into M2 measurement for your laser. (Image courtesy of Lucasfilm)

How is laser beam quality measured?

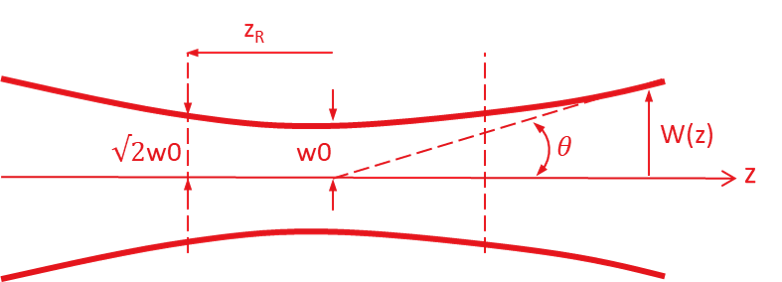

Several parameters are very useful to assess laser beam quality and properties. Among them are: M-squared factor (M2), divergence (), width at waist (w0), Beam Parameter Product (BPP), waist location, astigmatism, asymmetry, which can be calculated with conventional M2 beam propagation analyzers.

To reconstruct these parameters, such systems generally implement a camera that is moved along the laser propagation axis (z), either manually or by means of a translation stage, to acquire intensity maps of the beam. ISO 11146 standard defines that at least 10 observation planes are mandatory, half of them within one Rayleigh length (zR), the other half beyond 2 Rayleigh lengths.

What are the limitations of traditional M2 analyzers?

– Limitations include the fact that the translation has to be aligned respect with laser beam propagation, which takes time and limits the throughput in production. This is particularly true if laser manufacturing requires iterative steps and M2 measurements.

– Beam caustics must also be adapted to the available range of the translation stage, in order to acquire observation planes in and out the Rayleigh lengths. This is done by carefully choosing lenses of appropriate focal. Such lenses bring added aberrations to measured beam depending on their intrinsic quality and, again, quality of alignment. In addition, lens coating must also match the spectral properties of the laser. Such implementation results in voluminous benches, whose length is sometimes contained by internally folding the laser beam several times with the use of multiple mirrors. These mirrors also represent additional optical elements external to the laser.

– Last, the complete acquisition cycle requires time to scan the -at least- ten positions defined by the ISO 11146 standard. Any variation of the laser during this time affects the reconstruction of the M2 factor, which limits their use in case of dynamics effects.

New approach to laser beam diagnostics proposed by Imagine Optic

Imagine Optic proposes a new approach to conventional M2 beam propagation analyzers: in this method, the complete electromagnetic field of the laser is acquired from a single shot measurement and, from it, allows to access to as many observation frames within and out the Rayleigh lengths defined by the ISO 11146 standard and to fit the parameter M2.

Advantages of the method

Laser beam diagnostics is performed by Imagine Optic CAM SQUARED sensor:

+ It allows fast live acquisition thanks to its single shot acquisition (us to ms), making it perfect for alignment and characterization of laser or OPA dynamic changes

+ It is easy to set up, like a beam profiler, because there is no need to use a translation stage anymore, nor to align it on the laser beam ( 40 Seconds Demo Video )

+ This makes it a compact solution, with small footprint in the lab or on the production bench, and easy to handle for after-sales support and on-site service.

Avoid the path of Kylo Ren and don’t let a bad M2 factor ruin your day when there are quick and easy solutions at hand to test the quality of your laser beam. We are happy to discuss how they suit your needs. Reach us at sales@imagine-optic.com or through the contact form.

Why is M2 factor important?

The parameter M2 or beam quality factor- describes laser beam quality, or how close it is from a perfect gaussian beam: in this case M2 will tend to 1 and correspond to a diffraction-limited beam. M2 factor therefore describe the ability a laser beam has to be perfectly focused, or collimated (greater values than 1 means the laser departs from an ideal gaussian beam).

As an example, a HeNe laser typically have M2 factor close to 1.1.

What is the Beam Parameter Product (BPP)?

The Beam Parameter Product is the product of the beam radius at the beam waist and beam divergence half-angle () measured in the far field. BPP can be used to inform on beam quality of a laser -the lower the BPP, the higher the beam quality- but it presents the disadvantage of being dependent of the wavelength.