Shack-Hartmann wavefront sensor .

If Charles Darwin wasn’t thinking of the Shack-Hartmann wavefront sensor when he wrote his theory of evolution in 1838, it’s only because they hadn’t yet been invented. Since then, wavefront analysis technique has followed a steady evolution, accumulating inherited advantages combined with rapid adaptive leaps over almost a century, to become an optimum solution for modern optical metrology.

1900, 1st original idea by Hartmann

Around 1900, Johannes Franz Hartmann developed the Hartmann plate, consisting of an array of holes, which he used in combination with photographic plates to interpolate wavefront slopes and align telescopes.

1971, improvement by Shack (& Platt)

In 1971, Roland Shack and Ben Platt developed an optimized design for the Hartmann plate in which the array of holes is replaced by a much more efficient array of microlenses that concentrates light instead of widely blocking it, as with the mask.

Þ Combined with the advent of CCD cameras, this new approach has made the technique much faster, easier to use and adapted to “low light” applications such as astronomy.

Since then, the use of Shack-Hartmann sensors in optical metrology has continued to grow as they started to be used for laser testing, adaptive optics, ophthalmology for example.

1996, 1st commercial absolute wavefront measurement

Imagine Optic is established to materialize the vision of its cofounders: propose a reliable, easy to use and versatile tool for optical metrology at a time where only established alternative was the heavy, restrictive Fizeau interferometer.

Þ This is how the first Shack-Hartmann wavefront sensor offering live calibrated absolute measurement is commercialized as world premiere.

2001, first self-illuminated Shack-Hartmann

The LIP is born by combining our Shack-Hartmann wavefront sensor with an illumination feature in a built-in optomechanical platform.

Þ It optimizes optical quality and compactness of the solution in a ready to use to for transmission and reflection characterization of component.

2003, another patent

Imagine Optic turns the square apertures of the Hartmann plate, avoiding cross talk between adjacent sampling points.

Þ It allows to increase resolution and sampling of our HASO EUV Hartmann wavefront sensor operating at 248 nm.

2010, the advent of CMOS

Integration CMOS cameras as detectors for the wavefront sensors in replacement of the good old CCD.

Þ Customers benefit from faster and more sensitive sensors.

2015, broadband sensors

First Imagine Optic broadband Shack-Hartmann wavefront sensor offering absolute calibrated measurement in a wide 350-1100 nm spectral range with the HASO4 BROADBAND.

Þ Imagine Optic sensor precision of lambda/100 is now available for achromatic measurements at any wavelength

2017, instant setup feature

Invention of the SpotTracker which avoid preliminary alignment procedure to make optical setup easier and quicker.

Þ It brings absolute tilt measurement and follow up over large variations unlike lateral shearing interferometers.

2020, resolution breakthrough

Imagine Optic moves/transposes and optimizes Onera’s experts research on LIFT technology to a commercial off-the-shelf solution

Þ Ultra High Resolution becomes available to Shack-Hartmann wavefront sensors with HASO LIFT 680 with a resolution of 680×504 phase points which is unheard of!

2022, an Optical Engineer Companion for the lab

Launch of the OEC : Imagine Optic makes its wavefront sensors, beam adapter modules, illumination platform, metrology sources interconnectable modules such as LEGO® bricks.

Þ It provides versatility to create any optical configuration needed for metrology: any beam size, any divergence, any wavelength, transmission and reflection.

Imagine Optic metrology solutions then combines in a flexible optical lab tool that adapt to projects over time and can be upgraded function of future needs.

These innovations are only here to make your metrology more accurate, robust and easier to use. Stay tuned for more info about Shack-Hartmann wavefront sensor. We are happy to discuss how they suit your needs. Reach us at sales@imagine-optic.com or through the contact form.

What does a wavefront sensor do? What is the wavefront measurement?

A wavefront sensor measures the wavefront -a surface in which all the points have the same phase- of a light beam transmitted or reflected on an optical component (lens, windows, filter) or system (telescope, objective). The shape of the wavefront informs on the aberrations of the component or system and therefore on its optical quality and its performance.

What are the techniques used in wavefront sensing?

Apart from Interferometric methods, the wavefront can be measured by a large number of techniques, the most widespread of which is the Shack Hartmann wavefront sensing. Others include the Pyramid wavefront sensor, which can be assimilated to a scanning knife edge technique, Schlieren Imaging, a visual technique providing information on beam distortions, Wavefront Shearing Interferometry, a method measuring the slope of the wavefront such as Shack Hartmann wavefront sensing. Phase diversity uses a phase retrieval algorithm based on the analysis of intensity images and is declined in variants such as Curvature sensor and Generalized Phase Diversity sensors

How does a Shack Hartmann wavefront sensor work? What is the Hartmann shack method?

Operating principle of a Shack Hartmann wavefront sensor is very simple and compact, which makes them rugged:

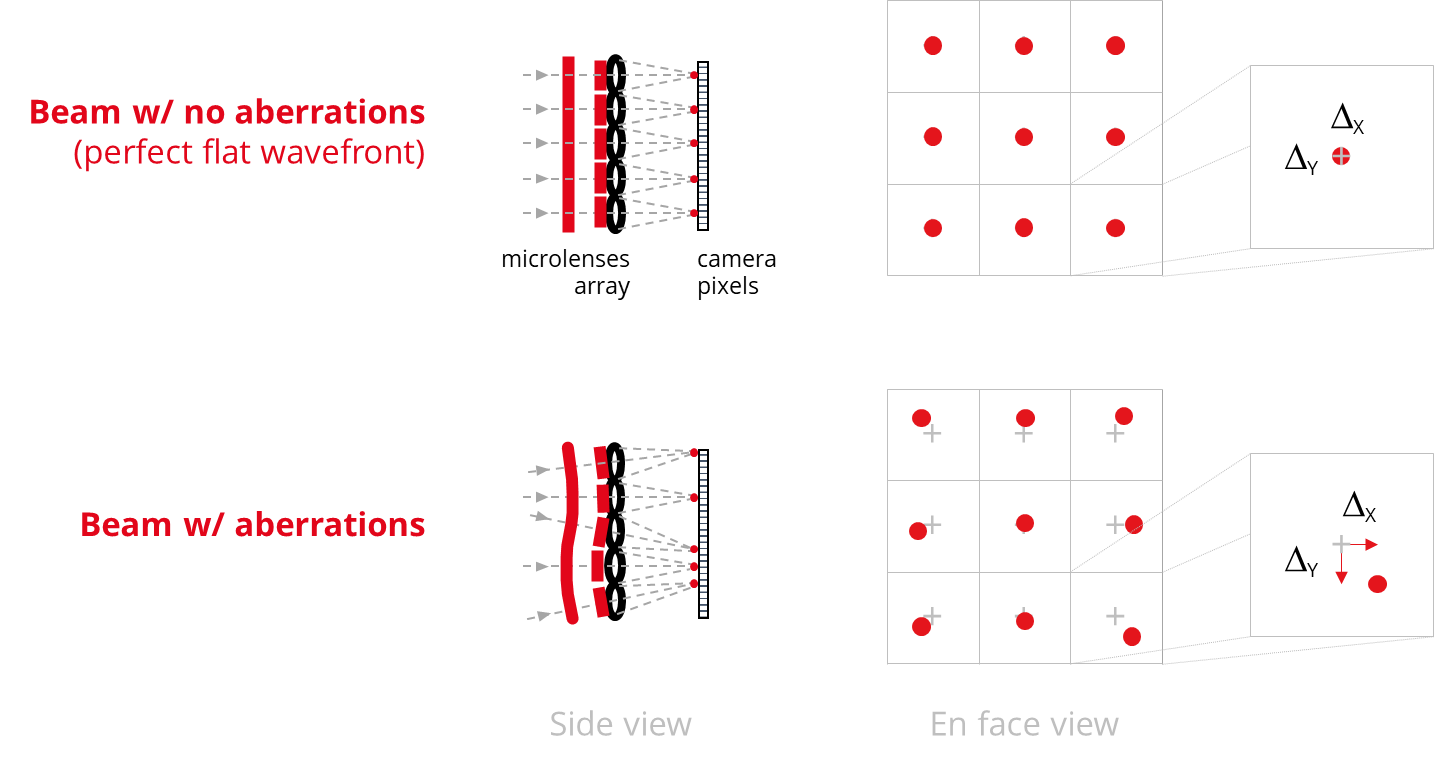

A Shack Hartmann wavefront sensor is made of two parts: an array of microlenses placed in front of a camera sensor. Each microlens samples the incoming optical beam by focusing a centroid on the detector. Analyzing the position of the centroids respect with their theoretical ideal position, one can calculate the slopes -or wavefront derivatives- as they correspond to the centroid displacement divided by the focal of the microlens.

What are the applications of a Shack Hartmann wavefront sensor?

Shack Hartmann wavefront sensors can be used for the characterization of optics, either in transmission or reflection, for the alignment of optical systems, taking advantage of the live feedback they provide, and to provide a signal to control the deformation of active components in adaptative optics and closed-loop systems.

Shack Hartmann wavefront sensors can be used in a wide range of application such as astronomy to measure telescopes or to correct atmospheric turbulences in free space optics; ophthalmology to characterize eyes for prescription, to guide lasik surgery or to control the correction of aberrations to better image retina in a variety of ocular diseases; microscopy, to control the correction of aberrations generated by thick samples; for laser beam diagnostic and collimation or measure broadband sources taking advantage that they can measure uncoherent light signal.