Mirrors Metrology

The metrology of mirrors during or after polishing is a key element to obtaining the desired optical quality.

Imagine Optic has developed a range of metrology solutions that allow precise and reliable measurement of mirror shape. Whether it is concave, parabolic or flat, Imagine Optic offers an adapted solution for each configuration.

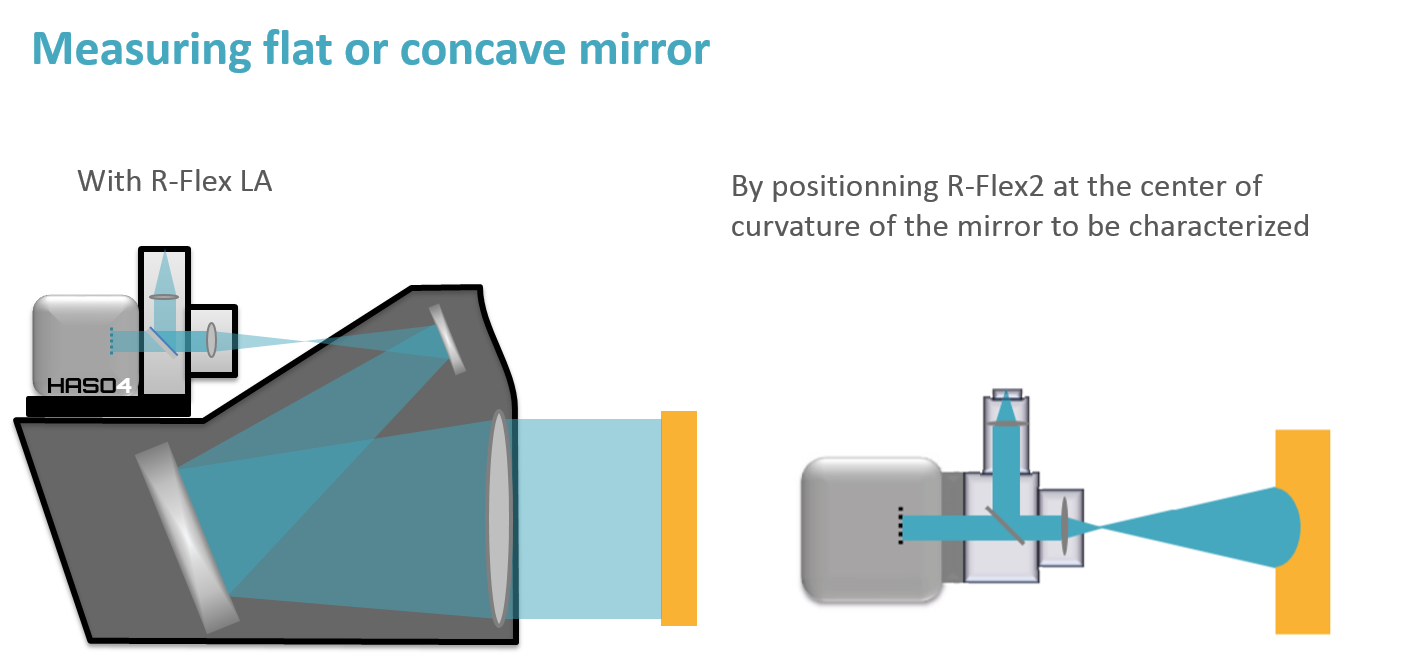

The R-Flex2 (self-illuminated wavefront sensor) is particularly well suited for measuring concave or parabolic mirrors. The R-Flex LA, which is used as a Fizeau interferometer, is the ideal system for the qualification of plane mirrors. These systems are insensitive to vibrations, and they have high measurement accuracy as well as a huge measurement dynamic. These characteristics make these mirror metrology systems both convenient to use and entirely reliable. In combination with the HASO LIFT wavefront sensors, these systems offer up to 340,000 measuring points on the surface of interest.

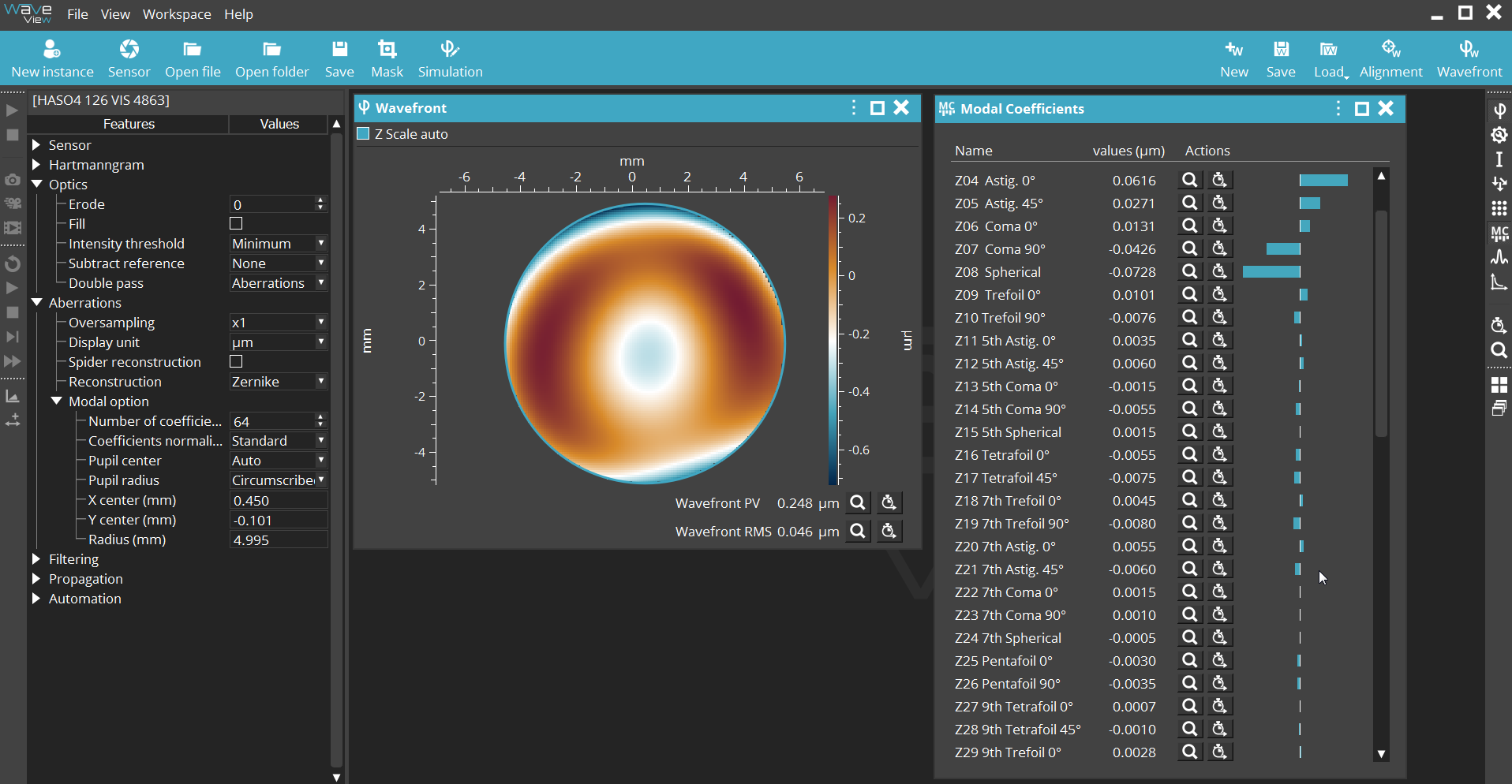

Imagine Optic offers a wide range of products (hardware and software), which can be used together to accurately characterize the optical quality of a complex optical systems. For instance the wavefront sensors from HASO line are perfectly suited for metrological characterization.

They can accurately measure distortion, field curvature, wavefront error and optical aberrations. Based on a patented Shack-Hartmann technology, HASOTM wavefront sensors by Imagine Optic contain an association of a microlens grid and a detector in order to calculate local derivatives of the wavefront and this way it can reach the accuracy of /100 RMS (Root Mean Square).