Optical & Lasers Manufacturing

Precision wavefront sensing and optical metrology solutions empowering laser and optics manufacturing & beam quality

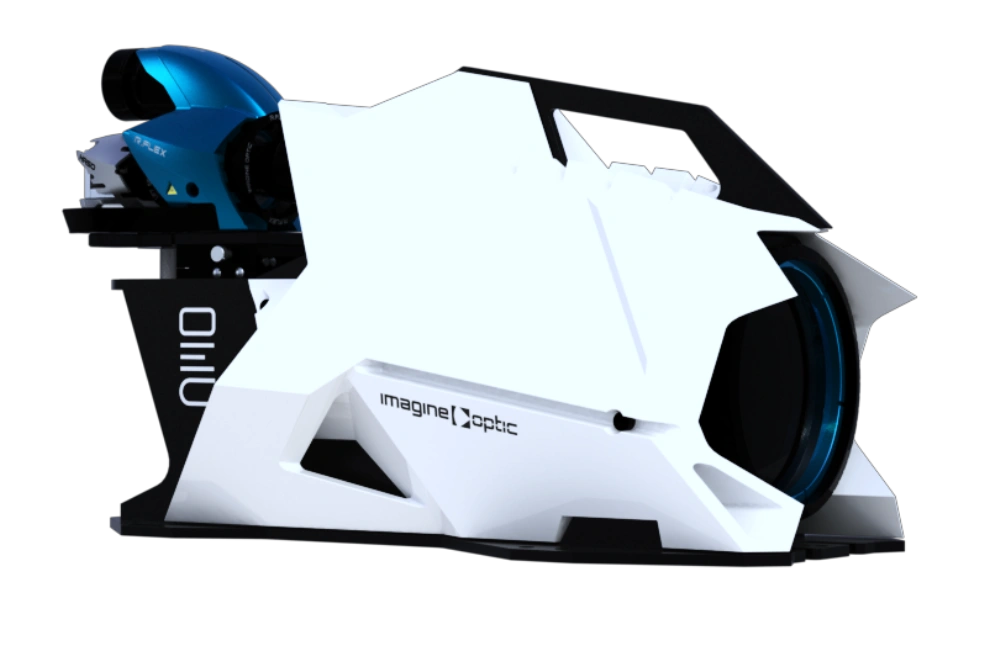

Imagine Optic provides comprehensive wavefront sensing and optical metrology solutions specifically designed for laser and optical manufacturing industries. Our flagship MESO metrology system offers robust, shop-floor optical testing of flat and plane-parallel optics with high-resolution wavefront measurements at multiple wavelengths, enabling precise process control and ISO10110 compliance directly on production lines.

Complementing MESO, the Optical Engineer Companion (OEC) platform allows modular, flexible configurations tailored to diverse optical metrology needs in R&D and manufacturing. For laser beam diagnostics and shaping, Imagine Optic delivers the high-performance M² meter for rapid measurement of beam quality parameters, combined with deformable mirrors (DMS) and adaptive optics platforms for real-time laser beam wavefront correction and optimization.

In-line optical metrology

The robustness of Shack Hartmann and phase retrieval technologies allows you to bring optical metrology closer to the production line, as they are insensitive to vibrations and atmospheric turbulence, avoiding the risk of moving samples and impacting production throughput. Their compact form factor and live calibrated measurements make them an ideal solution for in-line and end-of-line testing.

Optical components & assemblies

Choose your solution for fast, non-contact testing of optical parts, in transmission or in reflection. Dynamically align and optimize complete subsystems. Our sensors and instruments enable high-resolution achromatic sensing for applications in X-Rays, EUV, DUV, VIS, NIR up to SWIR wavelength ranges.

Sources/laser

For beam testing, collimation, beam pointing adjustment, alignment and aberration control of lasers and complete optical paths up to delivery, choose a compact, easy and quick to set up M2 or wavefront sensing solution combining live phase and intensity measurements.

Implementations - OPTICAL & LASER MANUFACTURING

|

+ Optical characterization of components & systems In transmission (WFE)

|

+ Optical alignment of systems/optical setup + Laser characterization (M2) + Polarization testing of scrambler + In situ process control + Laser alignment & collimation |